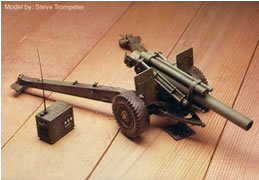

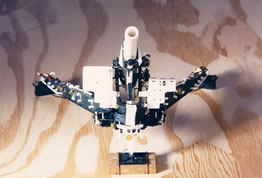

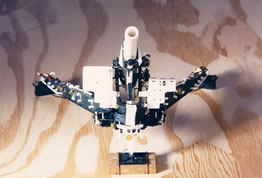

Building the Carriage Assembly

The

carriage also offers numerous areas for improvement. Since I did

not need to have the gun swivel, I was able to glue the cradle and

trails in place. This made the other detailing a bit easier since

I didn't have any rascally moving parts. The

carriage also offers numerous areas for improvement. Since I did

not need to have the gun swivel, I was able to glue the cradle and

trails in place. This made the other detailing a bit easier since

I didn't have any rascally moving parts.

- While

part 24 is bogus and only used to keep the gun elevation in place

when playing with the model, I glued it in anyway to allow me

to adjust the elevation for the purpose of the diorama, at which

time I did glue the gun in the trunnion (or cradle, as it's called

in the directions).

- Parts

33 and 34 are what I refer to in Item 6 on the howitzer construction

page, where the equilibrator attaches to the trunnion. I cut off

the pivot rods from these pieces and fashioned bits of Plastruct

to match the shape of the plates that were present. The equilibrator

end would be sandwiched between these two plates during the final

step of assembly.

- Because

it is an obvious detail when looking at the front of the gun,

I added a homemade elevating pinion to connect with the kit's

elevating arc between the trunnion arms; other bits were added

for housings that encased the elevating worm and elevating worm

wheel.

- The

traverse gearbox and shaft (part 31) needs to be mounted higher.

A junction was made for the traversing handwheel.

- Likewise

the work is necessary on the elevating handwheel shaft, which

passes through the trunnion to the elevating worm on the other

side. The shaft needs to for the elevating handwheel extends past

the farthest edge of the trunnion. The kit's handwheel is much

smaller than the real thing. I was leery of trying to scratchbuild

one myself, but I managed to successfully accomplish it the first

time out.

- The

telescope is extremely simplified. I basically deconstructed the

kit's parts and rebuilt them with added bits of brass and plastic.

- The

shields need to be thinned and reshaped. I used them as patterns

for new shields on thinner plastic card. I then recut them to

approximate the correct shapes. The shield on the gunner's side

does fold down, and is often seen folded while in use, so I constructed

mine that way. The shield on the other side is one piece, not

two as the kit portrays. On the outside of this shield are stowed

two rods used as ratchet handles for the firing jack when emplacing

the gun. Contrary to the kit, there is only one storage box, located

on the gunner's side for the gun sight. I used a little brass

box found in the model railroad section. Rivets were added where

necessary. The connecting points of the braces (parts 46) were

thinned and modified, and connected farther up the trunnion than

directed by the kit's instructions (the empty receiving points

in the trunnion were patched with plastic card). Missing triangular

shield braces were made from plastic card and detailed with rivets.

- I

carved off all detail on the sides and tops of the trails and

patched the holes. New stowage clips and holders for the handspikes,

ammo tray, jack float, rammer and aiming posts were made from

plastic and brass (it pays to hang on to any leftover photo etch

parts from your tanks!). Kurt thoughtfully provided measurements

of the placement of these items in his photos. These items were

welded onto the trails and I tried to indicate that with beads

of thick superglue. Grab handles were added to the outsides of

the trails, as were brackets to hold the spades in place while

the howitzer is traveled. A trail lock assembly was also scratchbuilt.

- The

kit errs in having brake fluid cylinders molded onto both the

trails and the interior face of the carriage. I ground off both

the incorrect cylinders on the carriage and the ones on the trails,

and correctly placed new ones (again brass pieces from the railroad

department) on the trails. I ran new conduit for the brake lines

along the inside faces of the trails. When the air brake lines

were disconnected from the towing vehicle, they were locked into

dummy couplings on the outer sides of the trails.

- The

ends of the trails need considerable attention. Rather than being

a solid hump over the top end, there are actually two protrusions

on either edge, with a channel running between them. I was able

to replicate this by drilling a hole through the center of the

hump, from one side to the other. I then filed down the center,

which gave me the end pieces and the channel produced by the drill.

The tow ring is secured to the left trail (as looking at the back

of the gun). I cemented the spades in place and added lifting

handles.

- The

plates (parts 50) to hold the trails to the carriage differ from

those in the museum photos, but I was not inclined to change them.

I glued the trails in place to the carriage, and then capped off

the plates with some brass coverings from the railroad department.

- Air

brake levers came from the Eduard 105 howitzer photo etch. The

brake diaphragms are more bits from the railroad department. The

latch plate and slack adjuster were handmade.

- The

firing jack was used to raise the carriage so the wheels were

off the ground and the gun's recoil didn't send the piece rolling

backwards. The kit's jack, again modified so it can be played

with, is the M1A2 postwar version. The tech manual and Mike Powell's

photos gave me enough info to scratchbuild the correct jack and

a new traveling lock. A canvas cover secured to the top of the

jack to keep it clean was made of tissue soaked in glue and secured

with wire. Another cover for the bottom of the jack was also scratchbuilt

and chained to the traveling lock. The kit's float that the jack

sat on was given a couple wire handles. Various pins and chains

were added where appropriate (chains were added after the kit

was primed to reduce help maintain the detail). The jack's ratchet

handles were stowed on the gun's front shield.

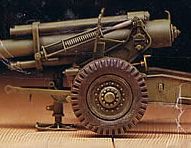

-

The most commonly seen wheels during the war were the diamond

pattern and the zigzag pattern treads. I first smoothed the road-contact

surfaces of the tires with an X-Acto knife and sandpaper. I tried

carving the diamonds with a Dremel but wasn't able to get the

angles without cutting into the grooved pattern around the edge

of the tire, which I wanted to preserve. I then attempted to replicate

the zigzag pattern around the circumference of the tire as a straight

line (the zigzag itself being impossible to reproduce), again

using an X-Acto. But again the results were unsatisfactory.

Several

modelers on Track-Link suggested using the rubber tires from

Tamiya's Dragon Wagon, which can be purchased separately. These

tires, while still not the correct pattern, are at least World

War II vintage, and the size is right on. One could argue that

they would be adequate replacements on the front line if the

right tires were not at the supply depot.

Using

these tires necessitated sanding down the Italeri wheel (#54)

between 1/8 and 3/16 inches. I test fitted the tires onto the

wheels several times, including the wheel rims (#57) on the

back sides, to make sure I didn't snd off too much. When the

tires were snug and no gaps present, I glued the rims to the

wheels, and the tires slipped over nicely. I spray painted the

wheel assembly before affixing the tires with some white glue.

As

you can see from my photos there are enough doodads added to make

handling the carriage an exercise in extreme caution.

Introduction

Background

on the 155mm Howitzer

Overview

of the Model and References

Building

the Howitzer Assembly

Building the

Carriage Assembly

Painting and

Accessories

Pictures

from the Technical Manual

155mm

Ammunition

Pictures

of Museum 155mm Howitzer

Diorama:

"Mail Call for the Sons of Thor"

|