Building

the Howitzer Assembly

The

model essentially breaks down to two assemblies: the howitzer and

the carriage, including the cradle and trails. The Italeri/Testors

pictures are of a finished model; click on my in-progress photos

with the border to open a larger picture in a new window.

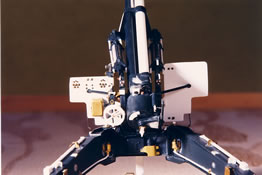

- The

kit's two-part barrel - more correctly called the tube - was replaced

with a 3/8" Butyrate tube from Plastruct, since the final

result of gluing the kit's pieces was that they were more oval

than round. The replacement tube had to be sanded down some in

order to fit within the barrel sleeve. I also replaced the recuperator

and recoil cylinders (parts 14 and 17) with 11/16" and 5/32"

Evergreen tubes. The closed tip of the kit's recuperator cylinder

was sawed off, adjusted and glued onto the open end of the Plastruct

tube.

|

|

The

breech was extensively reworked. It's designed to swing open or

closed, but I glued it closed (the breech block itself is significantly

undersized and would need to be reworked if left open). The breech

has a rounded extension on the right topside, featuring a circle

with a bar through it, which I removed. (The circle and bar is

actually on the back side of part 5 and I used a piece from the

Eduard photo etch for the M1 105 Howitzer to place this detail

on the reworked part 5.) A new squarish extension was added on

the left top of the barrel, to which the counter recoil cylinder

was attached on the real gun. The counter balance (part 66) can

be used, but needs to be turned around so the end that glues to

the breech is actually at the front (barrel side) of the piece.

I used some bits of plastic and Grandt Line bolts to create the

armature that connects to the top of the breechblock's hinge on

the side of the breech. A percussion hammer was added from brass

pieces. A lanyard was connected to this after the gun was loaded

and ready to fire. The

breech was extensively reworked. It's designed to swing open or

closed, but I glued it closed (the breech block itself is significantly

undersized and would need to be reworked if left open). The breech

has a rounded extension on the right topside, featuring a circle

with a bar through it, which I removed. (The circle and bar is

actually on the back side of part 5 and I used a piece from the

Eduard photo etch for the M1 105 Howitzer to place this detail

on the reworked part 5.) A new squarish extension was added on

the left top of the barrel, to which the counter recoil cylinder

was attached on the real gun. The counter balance (part 66) can

be used, but needs to be turned around so the end that glues to

the breech is actually at the front (barrel side) of the piece.

I used some bits of plastic and Grandt Line bolts to create the

armature that connects to the top of the breechblock's hinge on

the side of the breech. A percussion hammer was added from brass

pieces. A lanyard was connected to this after the gun was loaded

and ready to fire.

- The

kit's recuperator yoke (aka "cylinder yoke") is simplified,

likely due to molding purposes. I added some strips of plastic

card to replace the missing front flange. The bottom of the yoke

has a pin for the traveling lock, but this really should be cut

off and a hole made through this tab. The tab's corners should

be cropped, and a supporting flange added.

- Part

5 receives the back ends of the recuperator and counter recoil

cylinders (kit parts 14 and 18). Its shape is significantly simplified,

and I was able to create a more credible appearance using a small

file and some putty.

-

The elevator gear (part 4) had a strip of Plastruct added across

the narrow top edge, and three strengthen strips added to the

sides.

|

|

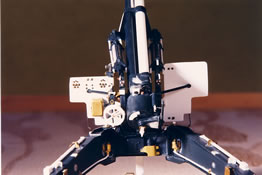

- The

pair of two-piece equilibrator springs was assembled, and when

dry they were carefully cut apart to remove the solid spring areas

and the adjoining flat plastic on the other side of the piece.

This left one remaining rod on each equilibrator piece. I glued

in springs made from thin solder wire, then pieces of Plastruct

rod to replace the missing parts. These rods were bolted at the

barrel end of the springs, and extended through the plate and

secured with nuts on the breech end of the springs. The middle

plate between the two ends has a hole in it in order to allow

the model's gun to be raised (the rods slide through these holes,

whereas on a real gun they would push against the sliding center

plate as the springs expanded). The hole was filled with putty.

While the kit is correct that the ends at the forward end of the

barrel were bolted to the sides of the cylinder yoke, the ends

that attach to the trunnion on the carriage are not bolted, as

the kit builds up. Rather, there were companion plates on the

outsides of the trunnion, and the equilibrator was secured between

those two plates. To accomplish this, you need to trim down the

attachment points on this end of the springs. (I did not glue

the springs, nor the howitzer assembly, in place for these photos,

as I planned to paint them separately from the carriage.)

-

Because I try to minimize breaking things during assembly, I often

leave small fragile parts off until the last possible moment.

I fashioned the percussion hammer and glued the breechblock lever

(part 67) just before painting.

Introduction

Background

on the 155mm Howitzer

Overview

of the Model and References

Building

the Howitzer Assembly

Building the

Carriage Assembly

Painting and

Accessories

Pictures

from the Technical Manual

155mm

Ammunition

Pictures

of Museum 155mm Howitzer

Diorama:

"Mail Call for the Sons of Thor"

|