These

photos will come in handy for modelers looking to create one of these

mobile shops with the

Calibre 35 maintenance truck conversion kit for Tamiya's GMC 2 1/2

Ton 6x6 "Deuce and a Half" (and which would likely work

on Italeri's open and hard-topped kits as well). These

photos will come in handy for modelers looking to create one of these

mobile shops with the

Calibre 35 maintenance truck conversion kit for Tamiya's GMC 2 1/2

Ton 6x6 "Deuce and a Half" (and which would likely work

on Italeri's open and hard-topped kits as well).

Michael

Powell has kindly provided the color photos. The black and white

images are from "The American Arsenal: The World War II Official

Standard Ordnance Catalogue" and the technical manual for the

M12 welding truck, the latter provided by Steve Malikoff.

There

were several types of trucks beyond those pictured below, including

the automotive repair truck, for general vehicle maintenance; the

electrical repair truck, for various types of automotive electrical

equipment; the instrument bench truck, to maintain and repair special

fire-control equipment; and the tire repair truck.

Of

the vehicles shown, only the machine shop welding trucks had their

own electrical generator; the others got their electricity from

other generators in the maintenance unit.

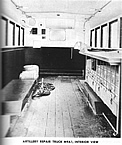

Artillery

Repair Truck M9A1 Artillery

Repair Truck M9A1

This

vehicle was used for maintenance of various artillery items by the

Heavy Maintenance Companies. Equipment included tackle blocks, rope,

chain hoists, a 1-ton collapsible tripod, electrical cords, portable

electric drill, vise, and various hand tools.

Instrument

Repair Truck M10A1 Instrument

Repair Truck M10A1

Used for repair and maintenance of optical instruments and equipment

(perhaps AFV sighting devices?), this truck's equipment included

a 10 inch bench lathe, drill press, 1/2 ton arbor press, electrical

bench grinder, surface plates with leveling screws, mandrel sets,

drill sets, clamps, gauges, assorted hand tools. Outrigger jacks

were provided to stabilize the truck for delicate repair work.

Welding

Truck M12 Welding

Truck M12

The M12 has a hardtop

cab. The generator is the same as the machine shop variant and powered

the arc welder. The images come from

TM 9-2852 on Welding Theory and Application, 3rd June 1943. According

to Steve Malikoff, it's a great TM and still very relevant on technique

and equipment, including a detailed chapter on how to repair shell

holes and cracks in armor plate using a variety of methods. This

lightproof welding screen and snap-on window curtains were provided

to shield the work being welded and prevent detection when welding

at night.

Machine

Shop Truck M16A1, M16A2 Machine

Shop Truck M16A1, M16A2

These trucks were used for general machine shop work. While M16A1

was basically a heavy lathe truck, M16A2 had a 10 inch bench lathe,

a 7 inch bench shaper, an electric bench grinder, a 10-ton hydraulic

press, and a special 1/2 inch drill press that was "very much

like a radial drill." It had a full complement of hand tools,

gauges, calipers, extractors, etc.

Signal

Repair Truck M30 Signal

Repair Truck M30

The

Signal Corps used this truck to repair radio, wire, and radar equipment.

The M30 had a shock-proof shell for carrying delicate testing equipment,

a small air compressor for cleaning purposes, a 12-volt battery,

battery charger, and additional electrical outlets for simultaneous

repair and testing of several pieces of equipment.

Small

Arms Repair Truck M7A2 Small

Arms Repair Truck M7A2

This was for weapons maintenance service. It features storage for

spare weapons parts and tools such as cartridge extractors and oil

stones, a portable weapons rack for storing rifles, and a portable

table to provide additional workspace outside of the truck. Tools

included a 3/8 inch portable electric drill and stand, bench grinder,

vises, hack saws, reamers, cleaning rods, gasoline torches, and

trigger weights, along with the common hand tools. While usually

getting electricity from another mobile shop truck, it could provide

its own juice with a portable, gasoline generator of 2-k.w. capacity.

-tss-

|